a

Sorbed gas reservoir systems represent a class of unconventional reservoirs where a significant proportion of the volatile hydrocarbons occur in the “sorbed” state (i.e. via the mechanism of sorption). Sorption entails physical bonding of volatile constituents that would otherwise occur as a gas, especially methane, with reservoir constituents existing in a condensed state (either liquid or solid). The most important sorbent in sorbed gas reservoir systems is sedimentary organic matter, in any of various condensed forms, particularly coal seams, kerogen, bitumen, or crude oil.

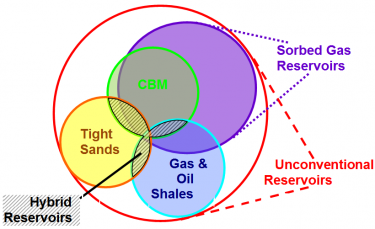

Owing to the concentrated character of sorbed gases, greater quantities of resources may be present than would be expected based on conventional gas volumetrics, especially at low reservoir temperature and pressure. Subclasses of sorbed gas reservoirs include coalbed methane, shale gas, and shale oil. (Note: black oil, solution gas, and volatile oil reservoirs also involve the mechanism of sorption, but are usually regarded as conventional reservoirs. The term “sorbed gas reservoir system” implies that multiple lithologies and multiple reservoir mechanisms may contribute to total production, making these reservoir particularly complex and challenging to characterize and understand.

The term sorbed gas reservoir does not imply that most of the production represents (de-)sorbed gas, as this proportion will vary, depending on the nature of the reservoir and when during the productive life of a well it is measured. For some hot, high pressure shales, the proportion of desorbed gas in the production stream is relatively low–at least initially–owing to the shape of the methane sorption isotherm. The proportion of (de-)sorbed gas will generally increase with time. For low temperature, low pressure, water-saturated coals and shales, sorbed gas represents effectively 100{5f5f0a671acf0b508101152deea4afb81c8dccec707e26097793c0a640d6907c} of the total throughout the life of the reservoir, as no free gas is initially present; and for shale oil reservoirs, such as the Bakken, sorbed gas may not be produced in the same proportions in which it is formed, as its more important role may be in expelling liquids and pushing them toward the production well (a process termed ‘solution gas drive’).

Venn Diagram depicting the intersecting classes of unconventional reservoir types. CBM (CSG) reservoirs produce mostly sorbed gas. Shale reservoirs produce a varying proportion of sorbed gas, depending on circumstances. Tight sands usually produce a small proportion of sorbed gas, if any.

In any of these examples, reducing reservoir pressure causes volatile constituents to transform from the sorbed state to the gaseous state, a process termed desorption. Desorbed gas may not become mobile until a critical free gas saturation is attained in the macroporosity (including fracture porosity). Thus, either gas or liquid, or some combination of the two will tend to migrate through the reservoir to points of lower pressure.

The same mechanism of physical sorption that enables these reservoirs to hold large quantities of sorbed hydrocarbons will also enable them to store substantial quantities of CO2 in the sorbed state, which makes them potential targets for sequestration of anthropogenic CO2, assuming limitations of permeability can be oversome.

They’re included as well!

Sorbed species can occur over a wide range of molecular weights. Pepper and Corvi (1995) presented an innovative treatment of the role of sorption in the retention, expulsion, and migration of hydrocarbons in both coal and shale. Although this model was developed to explain expulsion and fractionation of reservoir constituents over long periods of time, during petroleum generation, these concepts may be applicable to the production of liquids from shale reservoirs on a shorter time scale. In any case, sorption is a plausible mechanism for modeling movement of higher molecular weight fluids as well as gases. While coals have not typically been regarded as a source for produced liquids, this does occur in some locations (See Meek and Levine, 2005; Levine and Meek, 2005). Coals could very well be targeted for liquids production in the future, assuming permeability limitations can be overcome. Why not?

Despite the central role of oil and natural gas liquids in current exploration and production activities in North America, the term “sorbed gas reservoir” is still pertinent because of the important role of volatiles in the production process, even if they are not the principal target. Therefore, their behavior as sorbates, particularly their level of saturation, is likely to be a critical parameter controlling liquids production.

Rock on, gases!

(It’s a gas!)